Application

Application scenarios

1. Safe and non-toxic: Water soluble films are safe, non-toxic, non irritating, and easily degradable to humans.

After dissolving in water, the final degradation products are carbon dioxide and water, which can be absorbed by the human body and excreted through metabolism;

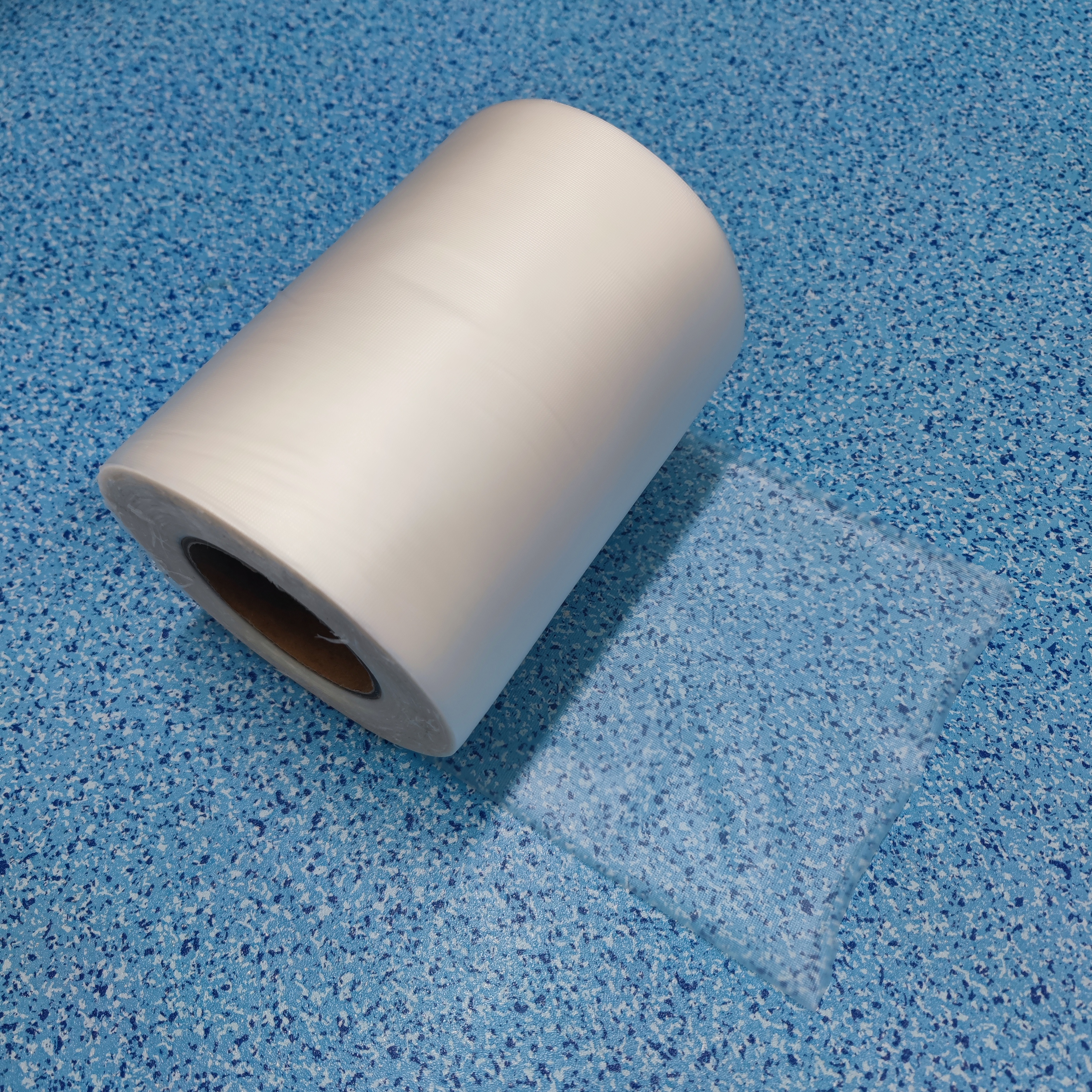

2. Environmentally friendly and soluble: Water soluble film is a soft thin film (with adjustable hardness) that is colorless, transparent, or colored opaque (with adjustable transparency). It can quickly dissolve in water (at 5 ℃ -30 ℃) within 2 minutes and completely dissolve within 50 seconds at temperatures above 30 ℃. Therefore, it can quickly release the contents of the film packaging, allowing the effective ingredients to quickly take effect. After the film dissolves, it becomes neutral and the ingredients do not pollute the environment. It is an environmentally friendly product;

3. Oil resistant and corrosion-resistant: The water-soluble film is insoluble in most organic solvents (such as benzene, xylene, etc.) and all animal oils, vegetable oils, and petroleum hydrocarbons, but soluble in glycerol, ethylene glycol, amides, triethanolamine, ethanolamine salts, and dimethyl sulfoxide;

4. Preventing static electricity: Water soluble film is an anti-static film that, unlike other plastic films, has good anti-static properties.

During the use of water-soluble film packaging products, there will be no reduction in plasticity or electrostatic dust adhesion caused by static electricity;

5. Elastic tensile strength: The water-soluble film has a thickness of 0.03-0.05mm, a tensile strength of 100-300 kg/cm2, an elongation of 10-600%, and a hardness of Shore hardness less than 10.

Due to its excellent flexibility, this film can be made into various sizes of packaging forms, allowing for easy bag making and processing;

6. Accurate measurement: Water soluble films have high mechanical automatic packaging performance due to their unique elastic modulus and tensile strength, making them suitable for various fully automatic filling machines and improving the accuracy of dosage;

7. Strong heat sealing ability: Water soluble packaging bags have good heat sealing ability, with a maximum heat resistance temperature of 140 ℃, suitable for resistance heat sealing and high-frequency heat sealing;

8. Breathable and Oxygen Blocking: Water soluble films have strong permeability to moisture and ammonia, but good barrier properties to oxygen, nitrogen, hydrogen, and carbon dioxide gases.

These characteristics enable it to maintain the composition and original odor of the packaged product intact, effectively protecting the activity of the contents and improving the effective use rate of pesticides;

9. Clear printing: Water soluble films can be printed with various desired color patterns on the film surface through ink, with good printability.

Key points for purchasing water-soluble film for p...

About PVA water-soluble film (including packaging ...

Can the self sealing bag of a water-soluble laundr...

How to treat water-soluble film after moisture abs...

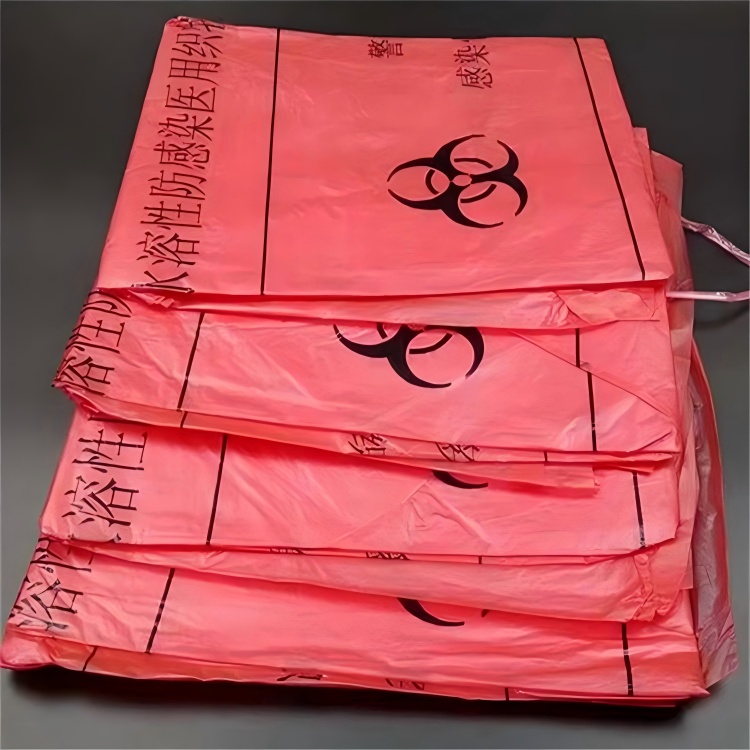

Water soluble anti infection medical fabric dispos...

How to choose the softness and hardness of PVA wat...

+ 86 - 755 - 8884 0106

f029@fujinfang.com

4B, Building A2, Xiufeng Industrial City, Gankeng Community, Jihua Street, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2010-2025 fujinfang.cn All rights reserved. Your Company name