Application

Application scenarios

Different application scenarios have different requirements for the softness and hardness of PVA film:

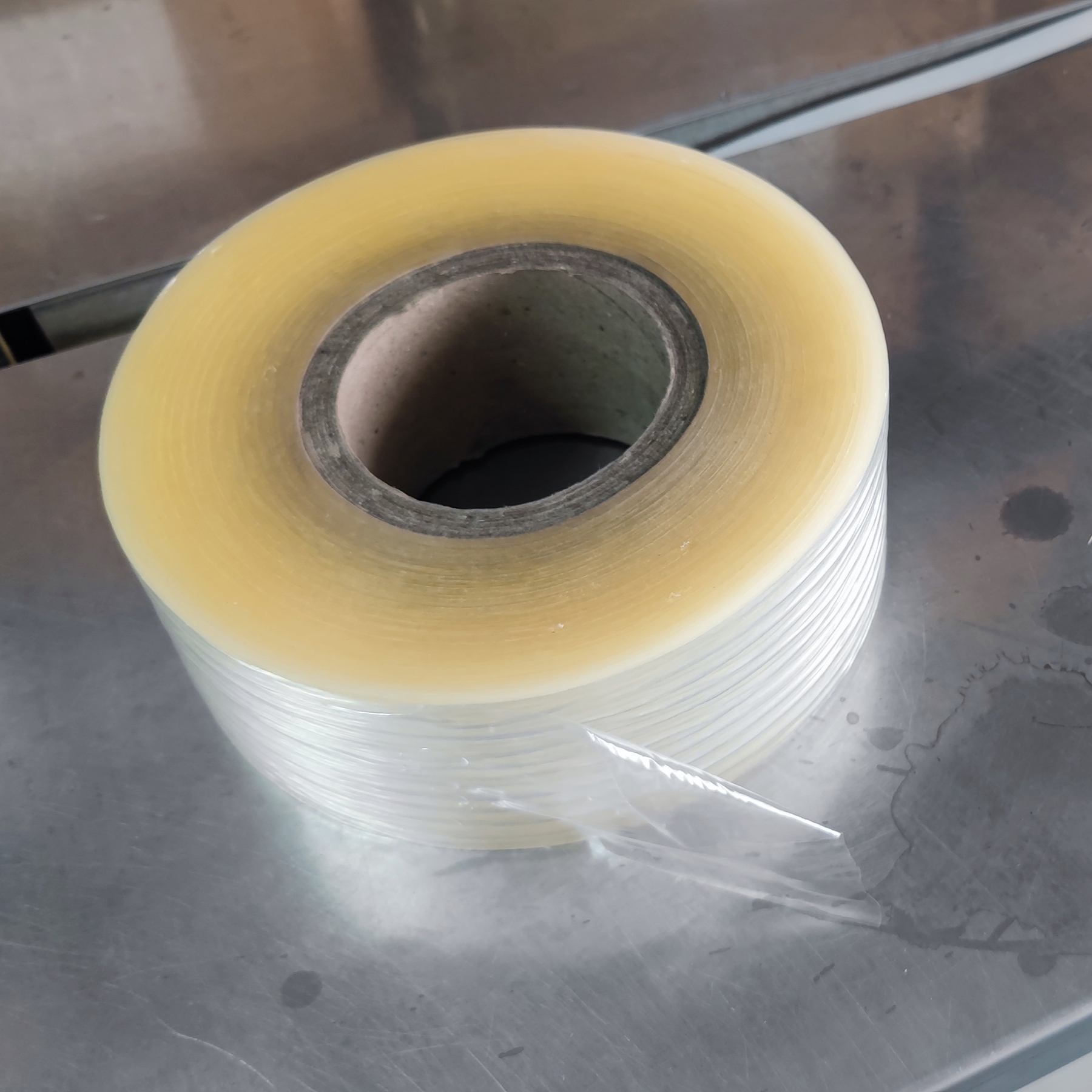

1. Scenarios that require high flexibility and extensibility:

Complex shaped packaging: The film needs to be able to fit the shape of the item well without rebounding.

Textile carriers (such as embroidery substrates, wigs): The film needs to be very soft to avoid damaging fine fabrics or hair.

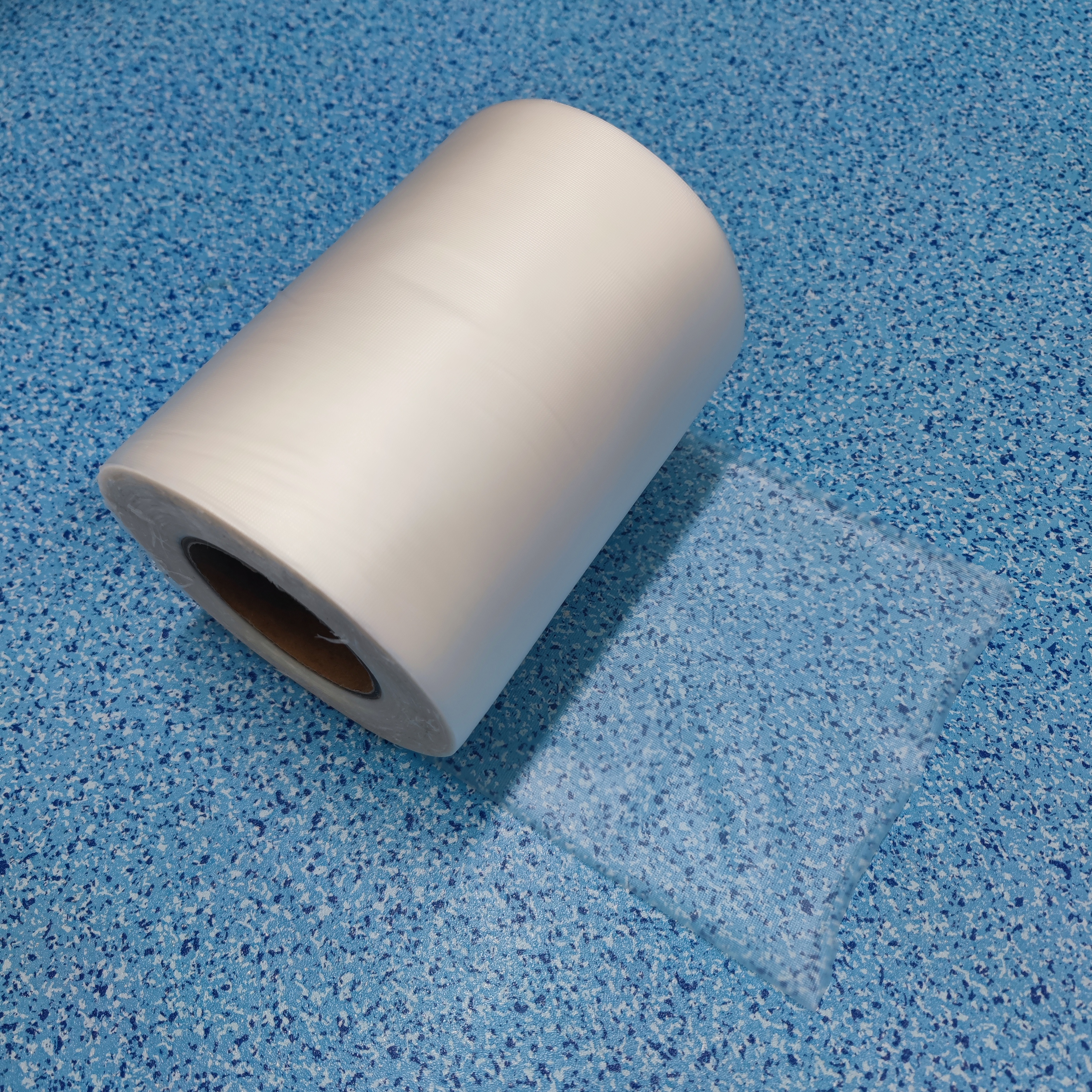

2. Scenarios requiring high hardness and strength:

Heavy packaging: The film needs to have sufficient strength to withstand the weight of the contents and not easily tear.

Printing substrate: requires film stiffness to ensure stability and accuracy during printing.

The softness and hardness of PVA water-soluble film are adjustable comprehensive properties, mainly affected by polymerization degree, alcoholysis degree, plasticizer, and thickness.

We need a soft and easily deformable film, pay attention to high elongation at break, choose low alcohol content grades, and add plasticizers.

We need films with high stiffness and strength, pay attention to high tensile strength, and choose grades with high polymerization and alcoholysis degrees.

I hope this information can help you better understand the softness and hardness characteristics of PVA water-soluble films.

Advantages of environmentally friendly packaging b...

Application of water-soluble film products

Can the self sealing bag of a water-soluble laundr...

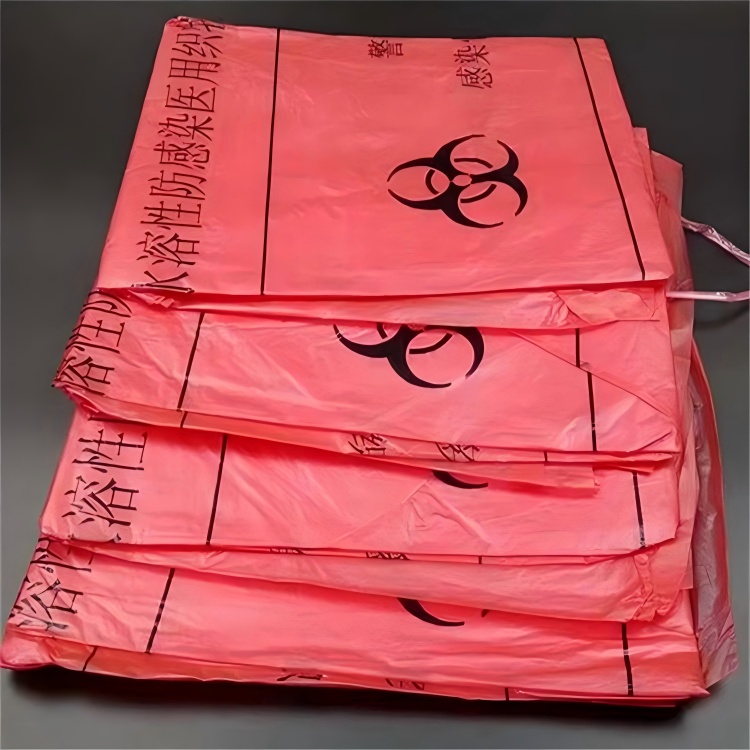

Water soluble anti infection medical fabric dispos...

How to identify the quality of water-soluble film ...

Key points for purchasing water-soluble film for p...

+ 86 - 755 - 8884 0106

f029@fujinfang.com

4B, Building A2, Xiufeng Industrial City, Gankeng Community, Jihua Street, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2010-2025 fujinfang.cn All rights reserved. Your Company name