Application

Application scenarios

How to identify quality issues with water-soluble film products? It is recommended to consider the following aspects.

1、 Water solubility:

Cold water soluble film (low-temperature water-soluble film) requires that it can dissolve in water at temperatures above 5 ℃.

The faster it dissolves, the better.

The less residue remains after dissolution, the better.

The clearer the dissolved water, the better.

2、 Appearance quality:

The smoother the roll, the better.

The outer surface of the rolled film should not have obvious bumps or wrinkles. The two end faces of the rolled film should be as smooth as possible, with a requirement of within ± 5mm.

The surface of the film should have no or minimal defects such as bubbles, perforations (except for cross stitch water-soluble films), slag inclusions, black spots, etc.

3、 Mechanical strength:

The tensile strength requirement is above 25Mpa (depending on the thickness of the film, the thicker the thickness, the greater the tensile strength).

Too little can easily break.

The higher the elongation at break, the harder the film, and the less it is, the softer it is.

The right angle tear resistance requirement is around 80KN/m.

Otherwise, it will be very brittle when it breaks.

4、 Storage time:

When stored in sealed packaging without moisture, water-soluble films with stable quality can be stored for 1-2 years or more.

Poor quality water-soluble films stored for less than 6 months, due to unstable quality, many chemical components will precipitate from the film, resulting in a lot of white dust. In severe cases, rolled films will turn dark.

Can the self sealing bag of a water-soluble laundr...

Characteristics of water-soluble packaging bags

Characteristics of Fluorescent Laundry Gel Water s...

Precautions for using water-soluble packaging film...

Application of water-soluble film products

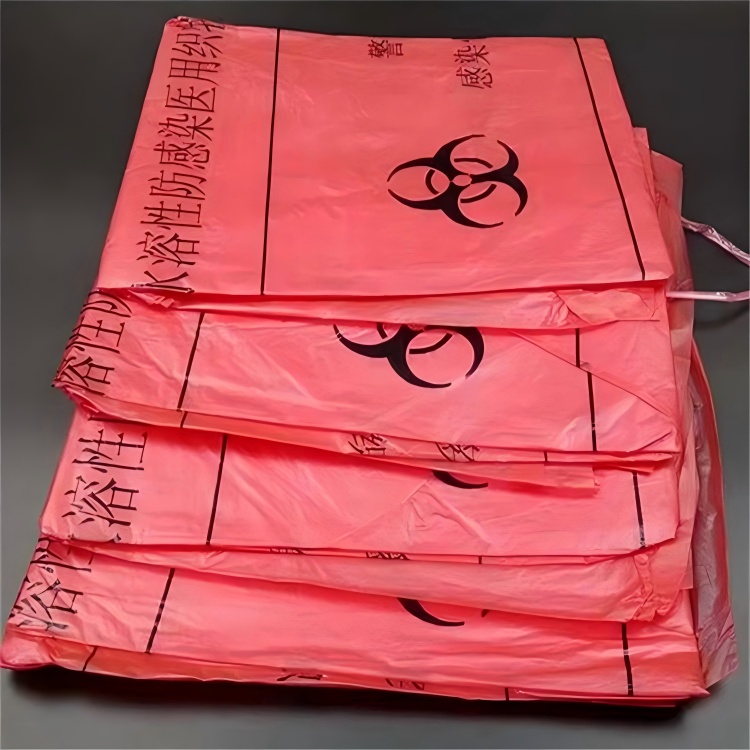

Water soluble anti infection medical fabric dispos...

+ 86 - 755 - 8884 0106

f029@fujinfang.com

4B, Building A2, Xiufeng Industrial City, Gankeng Community, Jihua Street, Longgang District, Shenzhen City, Guangdong Province, China

Copyright © 2010-2025 fujinfang.cn All rights reserved. Your Company name